Advance by UW–Madison scientists could help clear hurdle to plant-based fuels

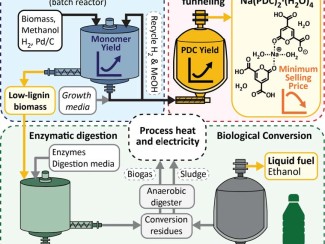

Microbes are key to turning plants into liquid fuels: Yeasts and bacteria eat plant sugars like glucose and turn them into alcohols, a process known as fermentation.

But when it comes to making biofuel from non-food plants there's a problem: most chemical treatments used to break down the plant fiber generate toxic byproducts.

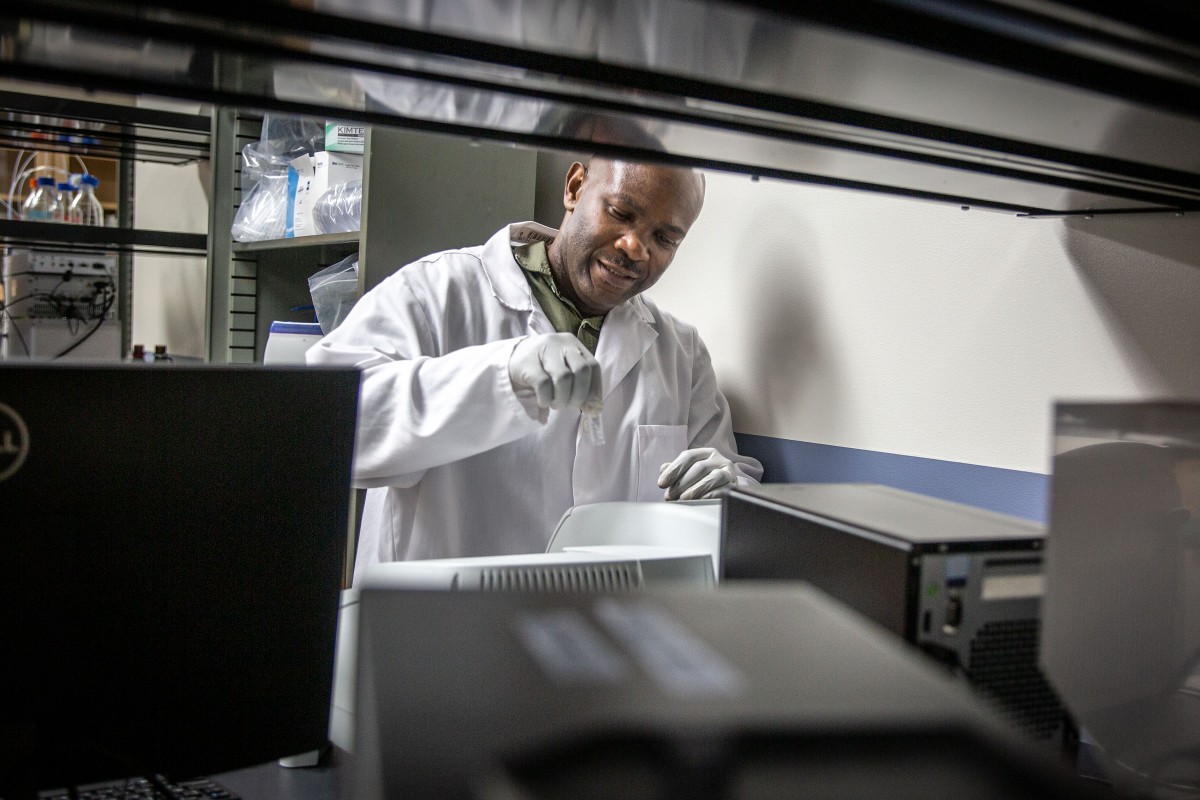

“One of the challenges with them is the inhibitors you get when you crack them open to get sugars,” said Victor Ujor, an assistant professor of food science at the University of Wisconsin–Madison whose research focuses on using microorganisms to convert waste into valuable products.

Ujor, a Wisconsin Energy Institute affiliate, has invented a genetically modified microbe that could solve the problem by removing toxins but leaving the sugar for other microbes.

The breakthrough could help pave the way for turning lignocellulosic biomass — such as grasses and trees — into a potentially limitless source of low-carbon energy that can be grown on land not suitable for food crops.

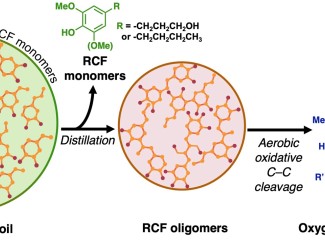

Making fuel and other petrochemical alternatives from these types of energy crops requires deconstructing the plant fiber to release the energy-rich sugars in cellulose and hemicellulose. This process typically involves harsh chemical treatments that generate toxic chemicals, primarily furfural and a related compound known as HMF, that inhibit fermentation of the resulting broth.

Many organisms naturally convert furans into other products, but those products can also limit fermentation.

“In the past, I’ve looked at different bugs that could reduce furfural and HMF to their respective alcohols, which are less toxic,” Ujor said. “But less toxic doesn’t mean non toxic.”

To solve the problem, Ujor wanted to find a microbe that would use furans as an energy source, removing them completely from the broth.

Some bacteria, including the soil-dwelling Pseudomonas putida, naturally consume furfural and HMF. The problem is they also eat the sugars.

So Ujor’s team set out to edit the bug’s genetic blueprint.

“We want to save the sugar for fermentation,” said Santosh Kumar, who led the project as a postdoctoral researcher in Ujor’s lab and is now an assistant professor of biology at McMurry University. “My purpose was to engineer a strain that can selectively utilize (furans) as a carbon source without touching the glucose, basically, and the other sugars.”

First, the scientists deleted three genes that enable P. putida to consume glucose, the sugar in cellulose. Then they inserted a cluster of genes from Cupriavidus basilensis, another soil microbe with an even greater appetite for furans.

And rather than randomly inserting the foreign genes, Kumar put them in the same place as the deleted genes, allowing the bug's native upstream promoters to activate the new genes.

“Glucose doesn’t get touched, and the furfural and HMF are mopped up,” Ujor said.

Unlike previous efforts to engineer P. putida, the team also added genes involved in forming transporters, valve-like proteins that move certain products through the cell wall.

“If you pull it into the cell quicker, you can metabolize it quicker,” he said.

The modified microbe, which Ujor has sought to patent, not only outperformed the native strain, it was able to handle furan concentrations two times higher than previously engineered strains.

Now the goal is to further tweak the genome to create a strain that can tolerate the higher concentrations of furans in real-world hydrolysates.

“Hopefully we can move it one notch up,” Ujor said.