The Great Lakes Bioenergy Research Center hosted a two-day conference to bridge traditional disciplinary divides and define a roadmap to guide lignin-based research over the coming decade.

Turning inedible plant fibers into transportation fuel has the potential to create a home-grown supply of clean and renewable energy and provide farmers with additional revenue streams without affecting food supplies.

But unlike traditional biofuels made from corn kernels and other starches, producing these cellulosic biofuels involves additional challenges — and opportunities.

That's largely because of lignin, a matrix of molecules (or polymer) that binds together sugars and provides structure, transports water, and helps protect plants against environmental stresses.

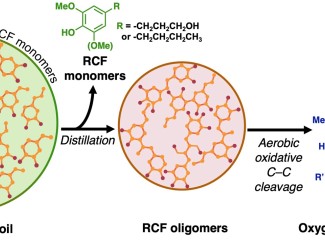

The second most abundant biopolymer on the planet, lignin is rich with ring-shaped molecules made mostly of carbon that can be made into substitutes for chemicals and fuels traditionally derived from petroleum.

Yet separating lignin from sugars often requires harsh chemical treatments that can poison microbes used to ferment the sugars into alcohols, and the complex and irregular structure make it hard to break apart into useful products.

Pulp and paper mills, which produce up to 70 million tons of lignin a year as a byproduct, simply burn it.

“Lignin is the Gordian’s knot of biofuels,” said Blake Simmons, division director of biological systems and engineering at Lawrence Berkeley National Laboratory and chief scientific and technology officer for the Joint BioEnergy Institute (JBEI) during a recent gathering of bioenergy researchers hosted by the Great Lakes Bioenergy Research Center at the University of Wisconsin–Madison's Wisconsin Energy Institute.

While it won't guarantee rule over Asia, untying the lignin knot could unlock opportunities for rural economies that haven’t benefited from fossil fuel production while also providing a renewably supply of low-carbon biofuels and products.

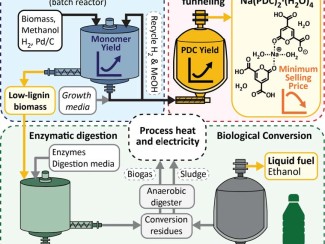

Just as with petroleum, where a small chemical fraction of each barrel accounts for up to half the profit, researchers see lignin as a potential source of high-value chemicals that can make biorefineries profitable while producing cost-competitive fuels.

The goal of the two-day conference was to bridge traditional disciplinary divides and define a roadmap to guide lignin-based research over the coming decade, said organizer Canan Sener, a GLBRC scientist who specializes in using catalysts to deconstruct biomass and convert lignin into valuable products.

Presenters included plant biologists, microbiologists, chemists, engineers, and computer scientists from four Department of Energy Bioenergy Research Centers (BRCs) who shared how their research informs strategies for improving cellulosic fuel production and extracting the highest value from lignin.

“Although the scientific approaches, tools, and questions varied — from plant engineering to microbial conversion, catalysis, and analytics — what united everyone was a shared focus on lignin,” Sener said. “By connecting these diverse efforts, we hoped to foster a more integrated and collaborative understanding of lignin across the entire value chain.”

Established in 2007 by the DOE's Office of Science, the bioenergy research centers — GLBRC, based at UW–Madison in collaboration with Michigan State University and other partner universities; the Center for Advanced Bioenergy and Bioproducts Innovation led by the University of Illinois Urbana-Champaign; the Center for Bioenergy Innovation at Oak Ridge National Laboratory; and JBEI — do foundational research to give industry the tools to make economically viable cellulosic biofuels and products.

Teams of scientists at each center study the workings of microbes, plants, and agricultural processes. Others perform techno-economic and life cycle analyses that can steer research towards the most economically viable pathways.

"We are all powerhouses ... on parallel paths," Simmons said.

GLBRC scientists have discovered ways to turn lignin into chemicals used to make plastics, dyes and adhesives, cosmetics, pharmaceuticals, and key additives in jet fuel as well as genetically modified trees with lignin that is easier to break apart. One lab is working to engineer plants that take in more carbon dioxide and turn it directly into useful chemicals.

The workshop was part of a broader effort to foster BRC collaboration on shared goals.

“BRCs are the perfect funding mechanism for solving these complex problems,” said GLBRC Director Tim Donohue, a professor of bacteriology at UW–Madison. “Federal investment to support a group of people working together is better than providing limited funding to researchers working in isolation.”

Researchers agreed that lignin valorization stands out as one of the best opportunities for collaboration.

“If we don't take this opportunity to show what we can do, shame on us,” Simmons said. “No one else is going to do it.”