The Science

Non-food crops like switchgrass are a promising source of plant-based fuels like ethanol and isobutanol, which can be produced by microbes. But switchgrass grown during droughts has high levels of chemicals that limit how much sugar these microbes can convert to alcohol. This experiment shows that breaking down switchgrass with ammonia, water, and enzymes and then lowering the acidity of the resulting hydrolysate solution both improve fermentation and biofuel production from switchgrass, especially when grown in drought conditions.

The Impact

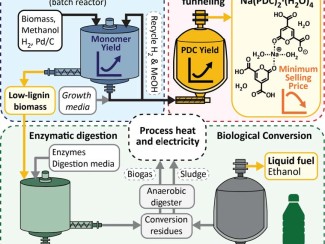

While electric-powered vehicles are a viable alternative to those powered by internal combustion engines, electrification is less viable for aviation. Sustainable aviation fuels made from chemically upgraded alcohols are a cleaner alternative to fossil-based jet fuel. Switchgrass, a heat and drought-tolerant grass that can grow on land unsuitable for food production, creates six times more energy than is required to grow it, making it a promising feedstock for alcohol-to-jet biofuel. Because extreme weather events such as drought are expected to become more frequent and intense as the climate warms, biorefineries will need methods to limit the impact on biofuel yields.

Summary

Switchgrass grown in Wisconsin during a severe drought in 2012 had higher levels of inhibitory compounds, resulting in lower fermentation rates by Saccharomyces cerevisiae than switchgrass grown under normal conditions.

Scientists with the Great Lakes Bioenergy Research Center explored whether the inhibitory effect of the drought switchgrass was specific to the ammonia fiber expansion (AFEX) pretreatment process and whether it could be alleviated by raising the pH of the hydrolysate. Switchgrass samples from drought (2012) and non-drought (2010 and 2016) years were pretreated with two methods, AFEX and soaking in aqueous ammonia (SAA), followed by enzymatic hydrolysis. The pH of both hydrolysates was adjusted to 5.0 and 5.8, and the feedstocks were fermented by S. cerevisiae and Zymomonas mobilis. Higher pH resulted in substantially higher biofuel production rates from both hydrolysates as well as two formulations of synthetic switchgrass hydrolysate. SAA pretreatment of drought switchgrass also enabled increased fermentation compared to AFEX.