Dairy is a $45 million business each year in Wisconsin. In the process of churning out massive quantities of milk, cheese, yogurt, and more, the dairy industry also produces tons of non-food residues, such as acid whey and milk permeates. Disposal of these leftovers poses an economic and environmental liability for farmers and processors.

A new project led by the Wisconsin Energy Institute at the University of Wisconsin–Madison seeks to turn this trash into treasure. Through a new collaboration with Wisconsin dairy industry stakeholders, the effort is developing processes to ferment dairy residues into organic chemicals and other useful products that can serve as a new revenue stream for farmers and support rural communities.

The university-industry partnership will help improve the economic and environmental sustainability of Wisconsin’s dairy industry by generating valuable, carbon-neutral products that will benefit producers, citizens, and the dairy sector, says Tim Donohue, professor of bacteriology, director of the Wisconsin Energy Institute, and principal investigator on the new project.

“This collaboration is but one real-life example of the Wisconsin Idea in action, working on the discoveries needed to decarbonize industries and provide benefit to citizens and local economies,” Donohue says. “Our researchers are already using these approaches to make valuable chemicals from other abundant agricultural and industrial residues. It’s a logical step to spin them off into this partnership with the dairy industry.”

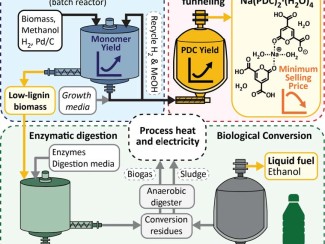

Funded by UW–Madison’s Promoting Industry Collaboration Initiative, the team will engineer microbial communities to ferment dairy residues into specific compounds of interest. The project offers the opportunity to upgrade agricultural wastes that have little to no food value into high-demand, industry-ready additives for the food, cosmetic, and other industries. In addition to Donohue, the team also includes professor of civil and environmental engineering Dan Noguera, who is working with the Wisconsin dairy industry to convert other dairy residues into valuable chemicals, and assistant professor of food science Victor Ujor, who has extensive experience using microorganisms for bioconversion.

The initial target compounds of the new project are lactic acid and succinic acid, two high-demand, industry-ready chemicals.

“Lactic acid is used for making biopolymers and bioplastics, and succinic acid has a lot of industrial applications, from agriculture to making composites and bioplastics,” says Ujor. “The demand is incredibly massive. Succinic acid is used to produce probably about 10 to 20 different other intermediate compounds in industry.”

Today, succinic acid is typically made from petrochemicals. But it doesn’t have to be that way, Ujor says. In fact, he says, “over the last decade, we figured out how to produce it from corn sugar using microorganisms, and the industry took off making it biologically.” But as the price of oil has dropped, profit margins shifted in favor of petroleum-based processing. In the past few years, chemical companies phased out bio-derived succinate.

“Right now, it's no longer commercially viable to produce it biologically. So what we're trying to do is to use whey, which is a much cheaper feedstock than corn sugar. Essentially, we're trying to make bio-derived succinate viable again,” Ujor says. “The demand is there, it's a matter of can we make it cheaply enough such that bio-succinate producers will be able to make profit?”

Whey could also offer a cheap alternative source of sugars for biological production of lactic acid, which is currently made via fermentation of food-grade sugars from corn.

A ‘Whey’ Forward

Whey permeate is a sugar-rich byproduct of turning milk into cheese, Greek yogurt, and other dairy foods. Those sugars make it a promising fermentation substrate, and with more than 25 billion pounds of milk being processed into whey permeates in Wisconsin each year, there is a consistent and inexpensive supply of the material. Right now, it’s treated as a waste product: Some dairy operations may spread whey permeates on fields to add organic matter to the soil. Others pay to send it to biodigesters to produce biogas, often at considerable cost. “We want to convert their burden into a resource,” Ujor says.

Previous attempts to ferment whey into succinic acid have failed to find a suitable microbe, Ujor says. With his expertise in engineering bacteria to convert waste materials into useful products, he will be working to design a microbial system that can tolerate the acidity of succinate and lactate, thereby producing high yields of both acids.

Ujor sees this project as an opportunity to position the state to take advantage of coming industry trends. “I think there is going to be a massive push over the next 10 to 20 years to expand our capability to make biodegradable plastics. Lactate is a big part of that,” he says. “So I think the industry is going to grow going forward. But whether we're relying on biologically sourced raw materials for that, or petroleum-sourced raw materials will depend on how much we can convert our waste to these chemicals.”

Working with industry partners from the earliest stages of research and development will help ensure compatibility with industry needs, standards, and production scale. Ideally, the project will lead to engineered microbial systems that industry partners can license to ferment their waste streams into an even wider range of chemical feedstocks.

“Most of all, we're creating new pools of products that can be produced from whey, and that means that whey becomes valuable for farmers in Wisconsin and across the country,” Ujor says. “Hopefully, it will be a catalyst for converting dairy waste, particularly whey, to value-added products.”