The history of energy-related research at UW–Madison, part 4

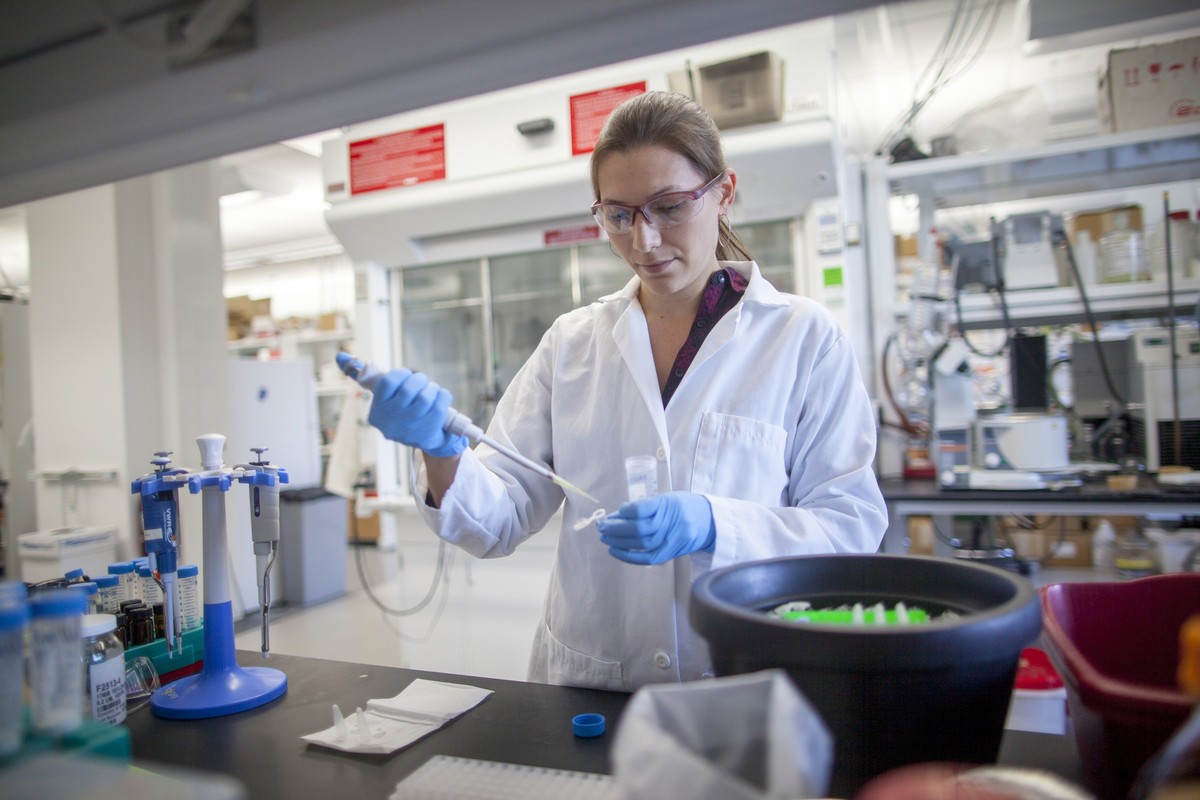

Tim Donohue never imagined that he would lead a multimillion-dollar energy research initiative when joined the university in 1986 as an assistant professor of bacteriology.

“I would have told you you need to have your head examined,” said Donohue, director of the Wisconsin Energy Institute and GLBRC.

Back then he was interested in how microorganisms conserved energy for their own functions, not harnessing their metabolisms to power airplanes and make plant-based plastics.

Scientists have long known that microbes produce alcohol and other solvents. Nearly 80 years ago, bacteriology professor Elizabeth McCoy patented a method for using bacteria to produce acetone and butanol.

Donohue said things changed at the turn of the century, when the Department of Energy’s Joint Genome Institute – having largely completed its goal of sequencing the human genome – turned its attention to microbes, allowing scientists to better understand what makes them tick.

“We were doing experiments in the dark,” he said. “It wasn’t until 2000 that we had the blueprints.”

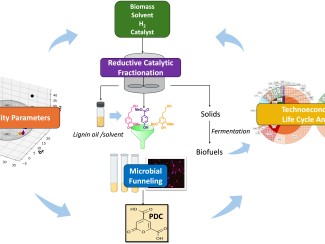

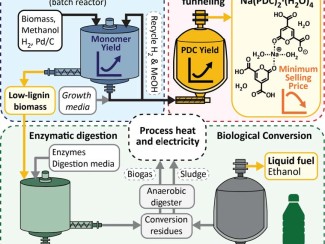

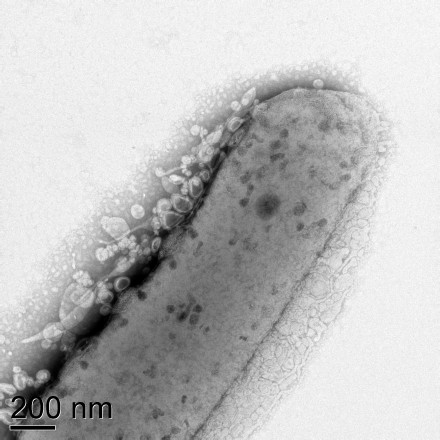

Using those blueprints, GLBRC scientists can now rewire yeast to eat different types of sugars or engineer bacteria to produce specialty fuels like isobutanol, which can replace gasoline and jet fuel.

Researchers are also leveraging this knowledge to produce an array of valuable chemicals – including those used to make plastics – from plant fibers, which is key to making plant-based fuels economically competitive with fossil fuels.

“It’s enabled so many things,” Donohue said. “We’re now at the point where we can really talk seriously about biology being the foundation of a whole new bioeconomy.”

In 2007, Donohue landed a $125 million grant from the Department of Energy to establish an interdisciplinary center tasked with doing the basic science needed to make cellulosic biofuels – made from non-food plants like grasses and wood – competitive with fossil fuels.

The energy department has twice renewed that grant, most recently in 2023, making GLBRC the largest federally-funded project in the university’s history.

The research goals support a three-pronged plan to eliminate carbon emissions from transportation, the nation’s largest source of heat-trapping gasses.

While that plan depends largely on battery-powered vehicles charged with clean electricity, electrification isn’t practical for applications like airplanes, ships and long-distance freight shipping. And even with widespread adoption of EVs, there will still be millions of older combustion vehicles on the roads after 2040.

That’s where plant-based fuels and chemicals come in, Donohue said.

GLRBC are coming up with ways to use microbes to produce hydrocarbons from plants like switchgrass, sorghum and poplar that can be grown on land that is unsuitable for food crops.

Such fuels use carbon from the atmosphere instead of deposits trapped underground for millions of years, making them carbon neutral – and in some cases resulting in a net reduction.

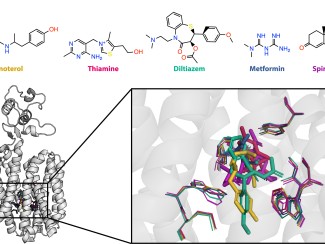

Much of the GLBRC’s work is focused on the production of chemicals – including key ingredients in plastics as well as inks, dyes, pharmaceuticals, and food additives – from parts of plants that are rich in hydrocarbons but notoriously difficult to break down into usable components.

The goal is not only to produce sustainable alternatives to these fossil fuel byproducts but to extract the highest possible value from every ton of biomass. Just as with petrochemicals, every molecule counts: Low-volume, high-value products help keep the fuel more affordable.

Donohue said there’s really no limit to the chemicals that microbes can produce.

“Microbes have been doing chemistry longer than people,” he said. “I think time will show that microbes can make more things than people can.”