Scientists in Jason Peters' lab have patented genetic tools used to study and modify bacteria that power production of biofuels and chemicals made from plant fiber.

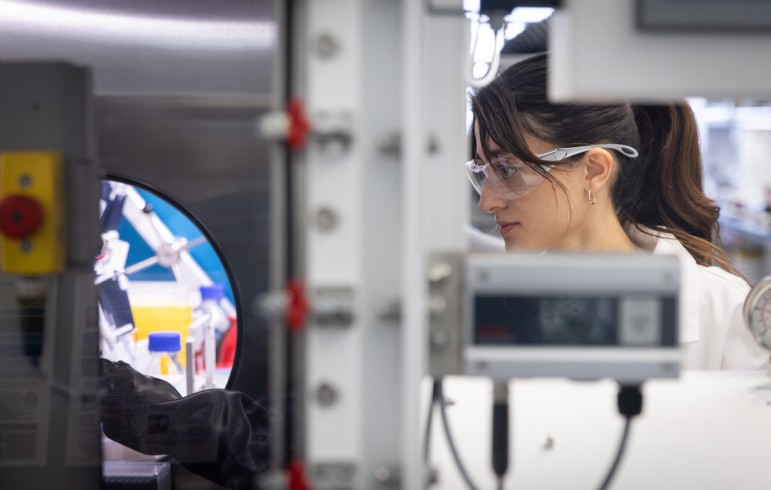

A research assistant in Victor Ujor’s lab, Eric Agyeman-Duah is a doctoral student in the food science program at UW Madison.

Building on previous work evaluating stepwise processing, scientists with the Great Lakes Bioenergy Research Center sought to improve the results with a biorefinery design that combines the first two steps, separating lignin from sugars and breaking into useable pieces with the help of a metal catalyst.

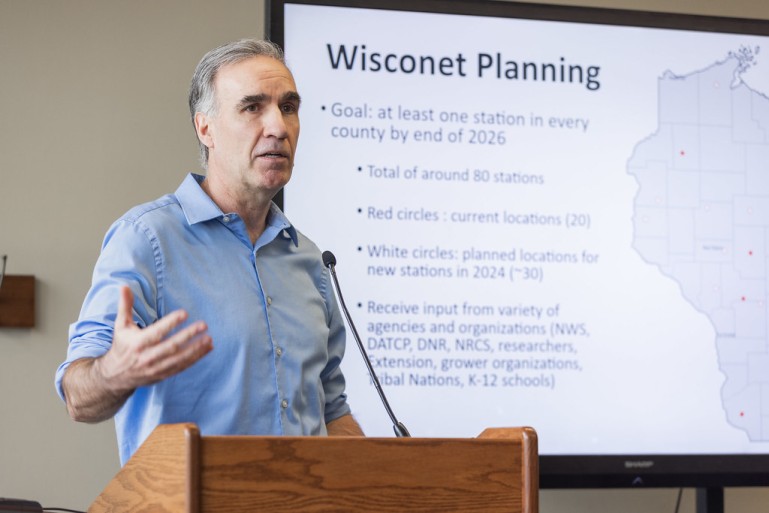

From microbes to cement and atomic-scale modeling to statewide weather monitoring, Wisconsin Energy Institute researchers use both cutting edge and tried-and-true technologies to expand basic knowledge and apply it to real-world problems. Here are a few of the highlights from 2025:

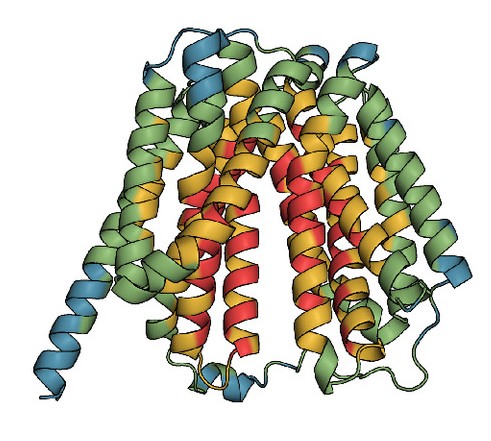

University of Wisconsin–Madison scientists have developed a new method for efficiently pinpointing genes that help microbes resist toxic chemicals, which could enable innovations in biotechnology, medicine, and agriculture.

Wisconsin Energy Institute investigator Dan Ludois has been named a fellow of the National Academy of Inventors.

A team of researchers including one current and one former Wisconsin Energy Institute affiliates has been honored for their efforts to engineer soybeans that produce an eco-friendly dye and a brain-boosting compound.