GLBRC and NREL collaboration combines copper-catalyzed oxidation and biological funneling to convert lignin oligomers to valuable bioproducts.

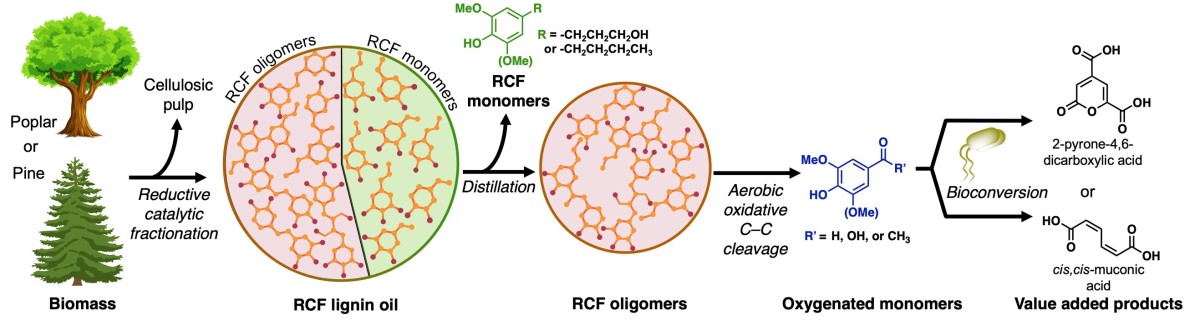

Copper-catalyzed aerobic oxidation converts oligomers from reductive catalytic fractionation (RCF) of poplar and pine biomass into aromatic monomers that are biologically transformed into industrial platform chemicals.

The Science

Efforts to produce sustainable fuels and chemicals from non-food plants focus on lignin, a part of the cell wall that binds together sugars and gives plants structure. Lignin contains ring-shaped molecules known as aromatics that some microbes can convert into chemicals used to make plastics and other products. But breaking this complex matrix — or polymer — into smaller, useful units is challenging.

Current methods for deconstructing lignin into individual units (monomers) mostly break carbon–oxygen bonds. This limitation leads to the formation of larger units (oligomers) with carbon–carbon bonds that microbes can’t digest. Here, scientists with the Great Lakes Bioenergy Research Center used oxygen with a copper catalyst (a helper that speeds up reactions without being consumed) in a special reactor to break those carbon–carbon bonds in oligomers created by the deconstruction of pine and poplar wood. Collaborators at the National Renewable Energy Laboratory then used engineered bacteria to “funnel” the monomers into industrial platform chemicals.

The Impact

Lignin is the world's most abundant source of renewable aromatic compounds that can be used to make sustainable plastics, adhesives, medicines, and other products. Conversion of lignin is also key to making cost-effective biofuels from crop residues or trees and grasses grown for bioenergy production. This combination of chemical and biological processes enables efficient conversion of less-valuable oligomers to molecules that can be easily converted to valuable products, maximizing yields of bioproducts from lignin.

Summary

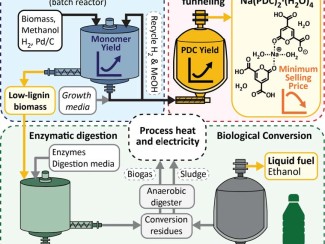

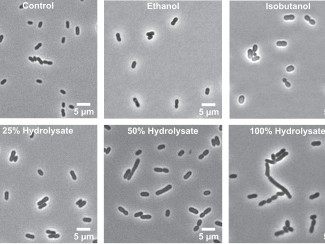

Scientists used copper-catalyzed aerobic oxidation under aqueous alkaline conditions to convert oligomers derived from reductive catalytic fractionation (RCF) of woody biomass into aromatic monomers used as feedstock for biological funneling to bioproducts. Optimal results were achieved in a flow reactor that provides precise control over oxygen delivery, temperature, and reaction residence time. An engineered strain of Pseudomonas putida (KT2440) was used to funnel the mixtures of oxidized aromatic monomers from pine to cis,cis-muconic acid (muconate) and from poplar to 2-pyron-4,6-dicarboxylic acid (PDC).

Monomer yields from RCF oligomers were higher or comparable to those from the best pretreatment lignin sources. Collectively, the pairing of RCF and oxidative C–C cleavage produced a total monomer yield of 33 wt% and 63 wt% aromatic monomers from pine and poplar RCF oils respectively. Muconate production from pine-derived oils produced a yield of 127 mol% (±11%), suggesting conversion of additional unknown compounds. PDC production from poplar-derived oils produced 57 mol% (±2%) yield.