New process reduces cost of plant-based platform chemical by nearly 30%

The Science

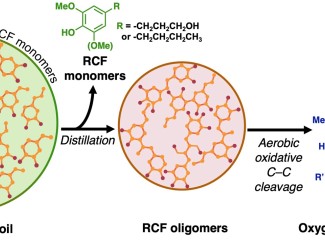

Plant biomass contains sugars and lignin, a long chain of molecules (polymer), that binds to sugars and helps the plant stand up. To be economically viable, biorefineries need to extract value from both — converting the sugars into biofuels and lignin into chemicals used to make plastics, adhesives, medicines, and other products. Recent biorefinery designs have used a three-step process: lignin is isolated from sugars with heat and solvents; then hydrogen and solvents are used to break down the lignin into individual units (monomers) and larger fragments (oligomers); genetically engineered bacteria “funnel” the lignin monomers into a chemical used to make bioplastics, while yeasts convert the sugars into alcohol. But this process is energy-intensive and leaves much of the lignin unusable.

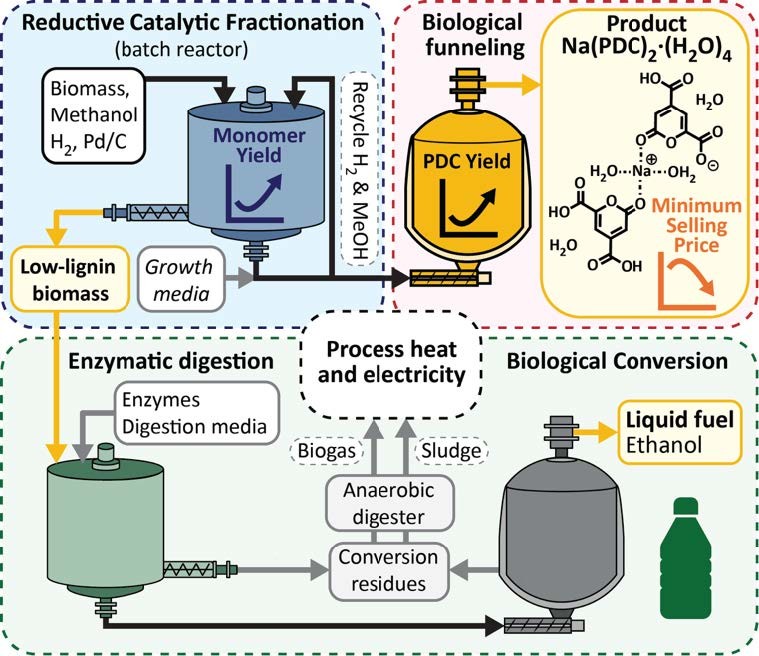

Building on previous work evaluating stepwise processing, scientists with the Great Lakes Bioenergy Research Center sought to improve the results with a biorefinery design that combines the first two steps, isolating the lignin and breaking it apart through a process called reductive catalytic fractionation (RCF). Raw biomass is placed in a high-pressure reactor with a solvent and hydrogen gas along with a catalyst, a helper agent that speeds up reactions without being consumed. This process yields a carbohydrate pulp, which is broken down with enzymes and fed to yeast, and a lignin oil that is easier to separate from the solvent and contains more monomers that can be converted into target chemicals, producing nearly eight times as much product per kilogram of biomass than the step-wise approach.

The Impact

Non-food plant fibers — including grasses, trees, and crop residue — can be a renewable source of biofuels and chemicals traditionally made from petroleum, but there are challenges that keep production costs high. The one-pot process requires less heat and solvent, lowering production costs, and it converts more of the lignin into usable monomers, resulting in a lower break-even selling price of the final product.

Summary

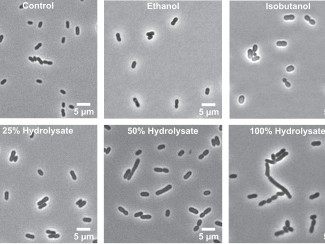

Building on previous efforts to increase the value of high-quality lignin isolated with γ-valerolactone (GVL) process, scientists with the Great Lakes Bioenergy Research Center treated poplar biomass in a pressurized reactor with methanol and hydrogen gas with palladium on carbon as the catalyst. Resulting hydrogenolysis oil was diluted in a minimal growth media supplemented with glucose and mixed with a strain of Novosphingobium aromaticivorans engineered to produce 2-pyrone-4,6-dicarboxylic acid (PDC). PDC accumulation produced a calculated yield of 58.5±3.5 g PDC/kg poplar, a 7.8-fold increase over the yield from lignin isolated with GVL.

RCF pulp was treated with cellulase enzymes to generate a hydrolysate. The catalyst was recovered from the hydrolysate via filtration, and the hydrolysate was inoculated with Saccharomyces cerevisiae. The ethanol production yield of 85.3% and yeast growth rates did not indicate the presence of inhibitors derived from the catalyst or hydrogenolysis residue in the pulp.

A techno-economic analysis of this process calculated a minimum selling price for Na(PDC)₂ salt of $18.39 per kg. The proposed tandem process leads to a $7.50 per kg (∼29%) reduction in cost. Using RCF increases the monomer/oligomer product yield through two synergistic effects: by retaining the soluble metabolites and small lignin fragments that were lost in the lignin isolation stage of the GVL-fractionation process; and by increasing the fraction of lignin in the biomass that is depolymerized to the RCF oil through elimination of acid-catalyzed lignin decomposition and condensation.