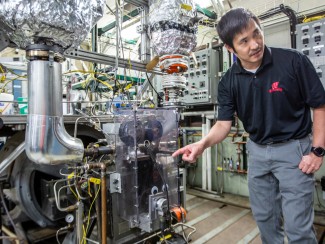

The flight of stairs between the ground floor and the basement of the University of Wisconsin-Madison’s Engineering Research Building separates a tranquil academic hallway from what looks—and smells—like a busy mechanic’s garage.

But instead of fixing cars, researchers are studying the internal combustion process itself to reduce the pollution, greenhouse gas emissions, and fuel consumption associated with modern transportation.

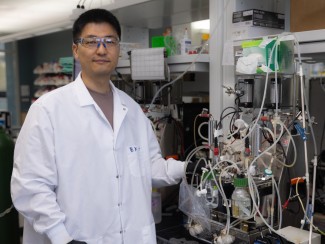

This summer, wielding pipettes rather than wrenches and lab coats rather than coveralls, engineers in UW-Madison’s Engine Research Center (ERC) are testing ‘green’ hydrocarbon fuels produced in the lab of James Dumesic, a professor of chemical and biological engineering and a researcher with the Great Lakes Bioenergy Research Center (GLBRC).

It’s a multidisciplinary project involving many areas of science, including physics, thermodynamics and chemistry.

“Our ultimate goal is to produce renewable fuels that you can blend with petroleum products at any proportion, from zero to 100 percent,” says ERC principal investigator David Rothamer, who is also a GLBRC researcher and a UW-Madison professor of mechanical engineering.

Rothamer and Dumesic are collaborating to determine whether the biofuel produced in Dumesic’s lab can be classified as a green gasoline. Meeting the necessary criteria would mean that the biomass-derived liquid qualifies as a ‘drop-in fuel’—one that could replace petroleum-based fuels in the current energy infrastructure.

“Hydrocarbon molecules of appropriate molecular weight could be directly dropped into certain fuels—it just depends on the structure of the compound,” explains Dumesic.

“A biofuel compound that’s relatively light, for example with six or eight carbon atoms, would be more appropriate for a gasoline additive. A heavier molecule, with maybe 12 or 16 atoms, would be more appropriate for jet fuel.”

Our ultimate goal is to produce renewable fuels that you can blend with petroleum products at any proportion, from zero to 100 percent.

David Rothamer

Many Americans may not be concerned with the chemical properties of the fuel they buy—and they don’t need to be. That’s because the American Society for Testing and Materials (ASTM) sets strict standards for gasoline sold at pumps in the United States.

“If we want to make a fuel that would act as a replacement for gasoline, we need to be able to meet the ASTM’s specifications,” says Rothamer.

Meeting these standards means testing the Dumesic lab’s biofuel, and then comparing the results with those from regular gasoline. In the Dumesic lab, researchers distill the biofuel into light and heavy portions; when ERC researchers receive it, they perform a separate battery of tests on each portion.

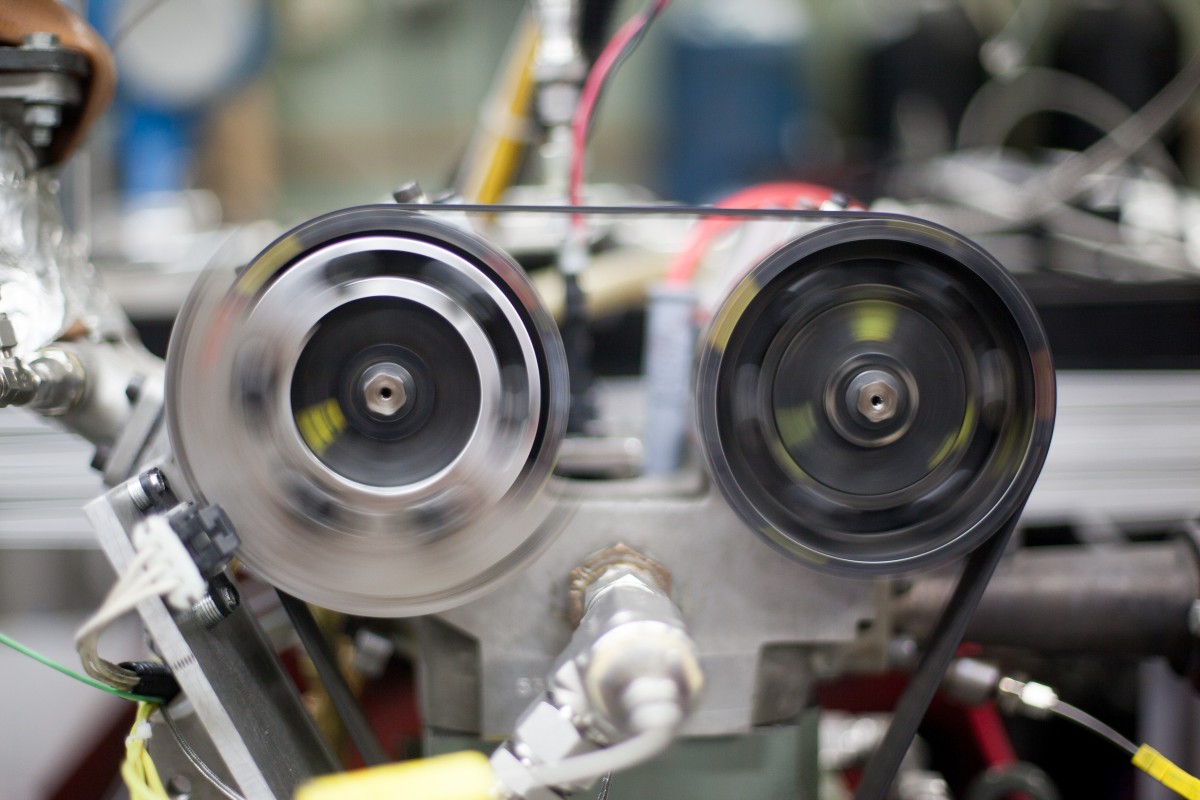

One of the most important ASTM criteria for gasoline is vapor pressure.

“Fuel needs to vaporize before it will burn, so looking at how the fuel vaporizes is very important,” says Jacob Backhaus, a former GLBRC graduate researcher who completed his master’s degree in mechanical engineering at UW-Madison this spring.

Vapor pressure is directly related to a compound’s volatility, or its tendency to change from liquid to vapor at a certain temperature. Because volatility has a big impact on engine function, the ASTM sets gasoline vapor pressure ranges for each state throughout the year to account for changes in seasonal temperature.

To help ERC researchers pinpoint the chemical components of a green gasoline that could meet ASTM volatility standards, Backhaus has developed a computer model that serves as a drop-in biofuel design tool. This fall, Rothamer and Dumesic will use Backhaus’s model to help coordinate their research.

“This is a really nice tool for us, because the model can tell us how many chemical components we need to replicate certain fuel properties in the simplest way,” says Rothamer. “These components are potentially present in the biofuels that Dumesic is making.”

One of the advantages of Dumesic’s biofuel method is that it can be tweaked in response to Rothamer’s modeling results. The process involves converting plant biomass into the volatile compound butene; using a chemical catalyst, Dumesic and his team can modify the molecular composition of the butene to get other chemicals that are better for burning in different types of engines.

“By controlling the catalyst and the reaction conditions of [our reactor], we can adjust the molecular weight distribution of the product to favor gasoline, jet fuel, or diesel fuels,” says Dumesic.

Results from tests on Dumesic’s biofuel will allow ERC researchers to identify which molecular characteristics must be changed to achieve drop-in biofuel status. By collaborating back and forth, the researchers aim to arrive at an engine-ready final product.

“The top requirement we're aiming for in these drop-in biofuels is that they ultimately operate the same way their petroleum-derived counterparts do,” says Backhaus. “The consumer should be able to put either one into their car and have it work exactly the same.”