A one-step, oxygen-driven method yields useful aromatic chemicals and plant sugars for biofuels

The Science

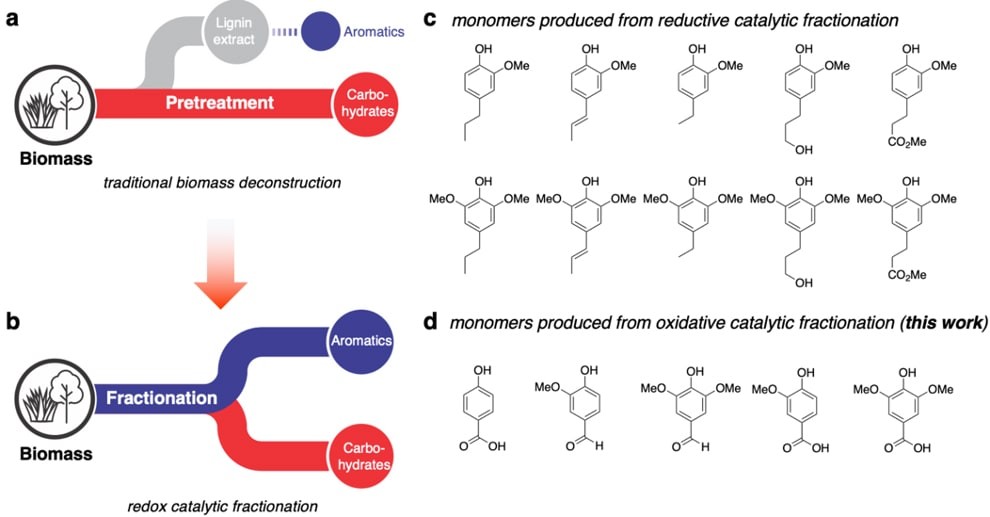

Breaking down plant material for biofuels processing has always required multiple steps, especially when it comes to dealing with the tough, complex polymer lignin. Current methods use a multi-step pretreatment process that focuses on extracting sugars to ferment into fuels. These steps leave behind the lignin, which is typically burned for energy. Chemists at the Great Lakes Bioenergy Research Center (GLBRC) have developed a new approach that converts biomass into both carbohydrates and lignin-derived aromatic monomers in a single step.

The Impact

The new process streamlines the conversion of raw plant material into two value-added product streams: sugars for biofuel production, and aromatic compounds for manufacturing and other industrial applications. Fewer steps should reduce processing costs, improving the economics of a biorefinery. The approach directly converts lignin from its native state into monomers. This approach avoids lignin degradation and mass losses that occur in traditional biomass separation methods and enables better product yields.

Summary

In the new study, GLBRC researchers describe a method to break down biomass in the presence of oxygen gas. A one-step, direct fractionation process yields carbohydrates, which can be fermented into biofuels, and a mixture of oxygenated aromatic monomers from lignin. The oxygenated monomers are complementary to those produced via processes that use hydrogen gas and include valuable chemicals such as vanillin and p-hydroxybenzoic acid, which are well-suited for industrial applications. The enhanced water solubility of oxygenated aromatics also allows for easier integration with other types of downstream processing methods, such as microbial funneling strategies that turn chemical mixtures into single compounds.

With a single reaction, chemists can produce compounds that previously required three or more steps. This approach should reduce the overall cost of biomass and help make plant-based fuels and chemicals more economically favorable. The process helps position lignin as a value-added product stream on par with plant sugars, rather than relegating it to a secondary or waste stream.

Program Manager

N. Kent Peters

Program Manager, Office of Biological and Environmental Research

kent.peters@science.doe.gov, 301-903-5549

Corresponding Author

Shannon Stahl

University of Wisconsin–Madison

stahl@chem.wisc.edu

Funding

Financial support for this project was provided by the Great Lakes Bioenergy Research Center, U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research, under Award Numbers DE-SC0018409 and DE-FC02-07ER64494. The NMR facilities were supported by the NIH (S10 OD012245), by a generous gift from Paul J. and Margaret M. Bender, and by the University of Wisconsin-Madison UW2020 program. The pXRD facilities were supported by a generous gift from Paul J. and Margaret M. Bender.

Publication

Luo, H., Weeda E.P., Alherech, M., Anson, C.W., Karlen, S.D., Cui, Y., Foster, C.E., Stahl, S.S., “Oxidative catalytic fractionation of lignocellulosic biomass under non-alkaline conditions.” Journal of the American Chemical Society (2021) 143 (37): 15462-15470 [DOI: 10.1021/jacs.1c08635]

Related Links

Press release on the research