Researchers from the University of Wisconsin-Madison, University of Minnesota, and Argonne National Laboratory will explore ways to produce renewable plastic precursors and other substances from biomass with a recently announced $3.3 million grant from the United States Department of Energy.

Part of a $13.4 million push by the Department of Energy to support the development of advanced biofuels and bioproducts, the grant plays to the strengths of a UW-Madison research community that already balances basic science with a focus on the processes needed to develop a diverse and economically viable suite of bio-derived chemicals.

“We’re trying to make very high-value commodity chemicals from biomass that can be used to make different kinds of plastics and plasticizers,” says George W. Huber, a professor of chemical and biological engineering at UW-Madison. “So many people have been focusing on fuels, which are a pretty low-value product—$600 or $700 per ton—but we’re going to be making products that are worth more than $5,000 per ton.”

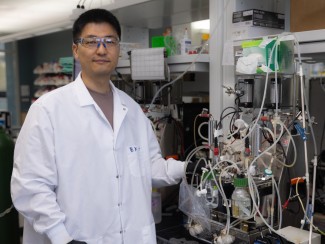

Joining Huber on the UW-Madison portion of the grant are Steenbock and Michael Boudart Professor of Chemical and Biological Engineering James A. Dumesic; Chemical and Biological Engineering Professor Christos Maravelias; Chemical and Biological Engineering Research Professor Bill Banholzer; and Chemistry Associate Professor Ive Hermans. This team of researchers, who also are affiliated with the Wisconsin Energy Institute, brings to the project combined expertise in biomass conversion, process design, techo-economic modeling of biochemical and biofuels production, and catalysis.

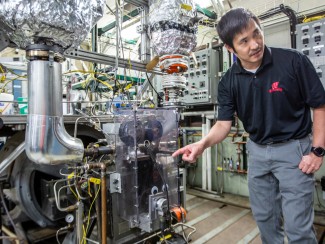

Researchers at Argonne National Laboratory will provide high-throughput tools for screening large amounts of catalysts used in the biomass-conversion process, and University of Minnesota researchers will contribute expertise in separating products from the reactants and solvents used in their production.

Huber says the three-year project will involve both elaborating the basic scientific principles involved in converting biomass into useful chemicals that are otherwise petroleum-derived, as well as developing efficient processes that can be scaled up in order to make bio-based production more competitive with petroleum refining.

“This is about developing new process technology,” Huber says. “We have some ideas about how to make these products, and really it’s to move the technology-readiness level. It’s about prototyping and demonstrating our ideas on a larger scale and getting this exciting technology a step closer to being commercially practical.”

Huber points out that bioenergy researchers at UW-Madison have a history of breakthroughs both in basic science and in the business side of bioproducts, from performing economically minded analyses to starting their own spinoff companies in the field.

“This shows the value of supporting basic research at universities and how basic research can translate to high-tech, high-paying jobs,” Huber says. “It’s important that Wisconsin doesn’t lose its expertise in terms of developing novel technology. I really think the University of Wisconsin is the international leading university in biomass-conversion to fuels and chemicals.”