Using a biomass-derived solvent, University of Wisconsin–Madison chemical and biological engineers have streamlined the process for converting lignocellulosic biomass into high-demand chemicals or energy-dense liquid transportation fuel.

Their new method eliminates the need for costly pretreatment steps that separate hemicellulose and cellulose, two main components of plant biomass that react at different rates. Pretreatment and extraction or separation steps can account for up to 30 percent of the total capital cost of a biofuels production plant.

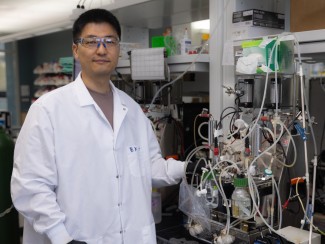

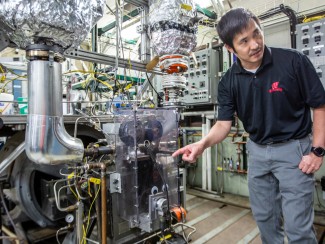

James Dumesic, the Steenbock Professor and Michel Boudart Professor of chemical and biological engineering at UW–Madison, and members of his research group described the process in a paper published online Nov. 1 in the journal “Energy & Environmental Science.”