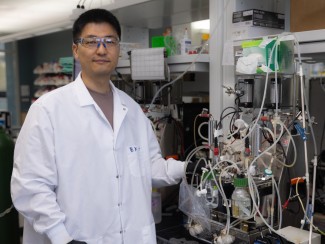

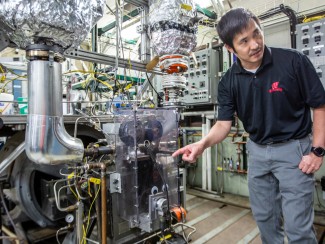

Jianping Li is the Keegstra Fellow exploring molecular modeling for chemical separations, working with Reid Van Lehn at the University of Wisconsin–Madison and Christos Maravelias at the Princeton University. He is developing a computational framework for designing solvent and extraction processes to separate and recover bioproducts from biomass in an efficient and cost-effective way. Jianping started his position in August. Connect with him via email at jli2367@wisc.edu.

Tell us a little about your background. What and where did you study before joining GLBRC?

I’m from Hunan Province in China. I did my undergraduate study in China at Dalian University of Technology, in chemical engineering. Then I did my Ph.D. at Texas A&M, also in chemical engineering. For that, I was working on some big picture issues like process intensification—basically, how to design a novel process that achieves significant process improvement. We worked on natural gas liquefaction, carbon capture, methanol synthesis and many other applications.

I was in College Station, which feels like a smaller town compared with Madison. It took three days for me to drive from Texas to Wisconsin in August.

How did you get interested in bioenergy research?

I found bioenergy topics through the connection to sustainability issues. And bioenergy is also an important part of smart energy systems, which is a rising topic currently in modern society. Smart energy systems synergistically combine electricity, thermal and gas grids with storage technologies. In smart energy system, biomass can be used to generate electricity/heat and to produce liquid fuels. Addressing bioenergy challenges is a very big challenge that we need to resolve, hopefully through research. I see this as a very important role that I can play to make some contributions to society, to have some impact.

How did you learn about this Keegstra fellowship?

I heard of this position from Professor Maravelias, and then I talked to him during the 2019 AIChE conference. From what he told me, it sounded like a very intriguing position with two different groups working together in the fields of molecular modeling and process system engineering. This type of position, combining two different research areas, makes me feel excited. I'm going to work with experts in molecular modeling, which I didn't have any experience in before, and I’m also interested in the applications of this project with implications for big-picture sustainability issues.

What will you be working on with the Van Lehn and Maravelias research groups?

Many bioproducts kind of aggregate in water, so we want to improve the quality of the bioproducts through separation. We're working on a project to design a separation method for bioproducts, choosing solvents to improve the separation. Meanwhile, we also want to find an ideal process flowsheet for that separation process. It's kind of simultaneous material and process design for bioproduct separation.

First, we come up with a lot of process configurations. Then we combine those process configurations into a single graph and we use an optimization approach to identify the best one. So we collect all the elements into a single set, and then we choose the best element from that set using an optimization approach. We can have many different criteria for what’s “best,” which we call an objective function. It could be minimizing the energy consumption, minimizing the carbon emissions, or minimizing the process economics, depending on what the user is expecting. Depending on different objectives, we might use different molecules as solvents. I'm learning many new things in molecular modeling.

One of our ambitions is to make the computational framework user-friendly so other people can design and screen the solvents for separation of bioproducts. This type of computational tool probably can relieve some of the effort of experiment design.

This program is about bridging different areas of research within the GLBRC. How will you be doing that?

This type of research area is already interdisciplinary by nature. Process system engineering combines the knowledge of applied mathematics and chemical engineering modeling, along with data science and some operations research to solve mathematical modeling problems. In terms of collaboration, I’ll be working with experimentalists for this project, which I haven’t really done before.

What do you hope to move on to after this position? What are your career goals?

I’m interested in academic positions, but I don't have any specific next destination that I want to go to. Process engineering is still a very interesting topic for me, and as I work with Professor Van Lehn’s group, I’m learning that product design is also very intriguing. As I read more on that, I’m finding that these product properties can also be very helpful in terms of process improvement. At the end, you might have an economic objective or a sustainability objective. Material properties give us another dimension to work on along with the process level. I hope to join a program where I can make a good contribution.

I'm also interested in starting a company in the future. It's a very early idea at this stage, it's not very mature, but I’m thinking about something in terms of product design that would apply the same techniques I'm learning here to some important, relevant application.

What do you like to do outside the lab?

I like watching scientific movies, and I also paint as well. Actually I've painted since I was six years old—sketches and color print painting. But these days I don't have much chance for doing that.

The Keegstra Bioenergy Research Fellowships are two-year postdoctoral appointments in integrative bioenergy sciences that promote interdisciplinary research in lignocellulosic bioenergy and bioproducts. Learn more