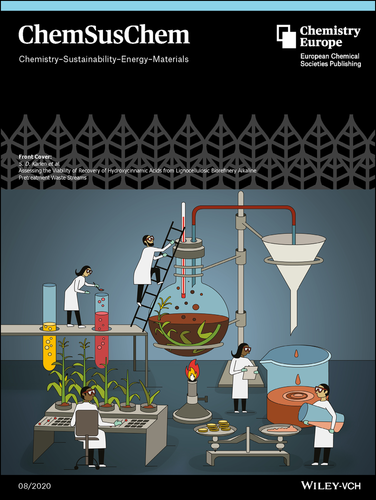

A large, collaborative Great Lakes Bioenergy research study published April 6 in ChemSusChem, is featured on the journal's cover.

The paper, "Assessing the Viability of Recovery of Hydroxycinnamic Acids from Lignocellulosic Biorefinery Alkaline Pretreatment Waste Streams," brings together a diverse team with expertise in many different fields to address a complex problem: how to make a biorefinery biologically and economically sustainable. Only by assessing the whole system, from field to the liquid fuels and co-products, can researchers identify the key parameters needed to design an economically viable, biorefinery-based economy.

In an accompanying cover profile, the lead researchers describe the study's importance and approach.

Why did this study take such a large team?

The Great Lakes Bioenergy Research Center (GLBRC), a Bioenergy Research Center funded by the U.S. Department of Energy and based at the University of Wisconsin–Madison, brings together experts in the different aspects of the biorefinery enterprise, from plant engineering, to characterizing the biomass and waste streams, through to integrating and evaluating the economics of the whole process. No one person or research team can have all the expertise needed to design a sustainable and economically viable lignocellulosic biorefinery. This is one of the GLBRC’s first papers that encompasses the full scope of the lignocellulosic biorefining process, from engineering the feedstock plant, pretreating the biomass, producing fuels, characterizing the waste streams, and calculating the overall economics of the biorefinery. None of these parts works in isolation. Putting all the steps together helps us identify our research goals and priorities as a community.

Why is this study important?

This study started out by assessing biomass pretreatment and recovery of two hydroxycinnamic acids, high-value chemicals that are naturally produced in plants and that are relatively easy to remove from the lignin backbone. Valuable coproducts such as these are an important contributor to the economics of the biorefinery. But to our surprise, we found that isolating and purifying two separate streams was not cost-effective, even for high-value products.

How do these findings affect biorefinery design strategies?

These findings highlight importance of selecting the best biomass feedstock, pretreatment, conversion, and isolation processes.

What’s next?

These results tell us that, for a biorefinery to be economically viable, we need to concentrate on funneling biological coproducts to a single useful product. This knowledge can guide decisions about feedstock engineering, pretreatment, and downstream funneling efforts such as those currently underway at the GLBRC using the microbe Novosphingobium aromaticivorans.