A vial of white sugar sits on Xuejun Pan’s desk beside a box of wood chips.

“It’s pretty pure and sweet,” he says, pointing to the sugar. “I’m not encouraging you. But it’s edible.”

With a new method being honed in Pan’s laboratory, the process of transforming tough plant material into powder-soft sugar takes only hours. The reaction is mild, fast and groundbreaking. No harsh pretreatment or enzymes are required. Low costs and sky-high sugar yields – that may exceed 90 percent – make Pan’s method one of the best in the business.

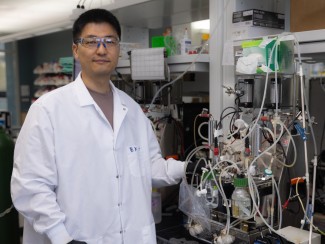

Standing in his lab in the Enzyme Institute, Pan swirls a test tube of syrupy extract. A murky layer of lignin settles at the bottom.

“Think about the future when we run out of oil. We may have solar energy, wind energy, nuclear energy and hydro. But what about the chemicals and materials currently derived from petroleum? Biomass likely is going to be the only option. Biomass-derived sugar will be the hard currency of the future bioeconomy.”

The work going on here is exciting because it has been speculated that biomass holds the potential to yield 1 billion tons of sugar per year in the U.S., equivalent to 80-150 billion gallons of ethanol. However, current methods to produce bioethanol from cornstarch or sugarcane are inadequate and unsustainable to meet the global demand for renewable fuels.