Driving the search for renewable fuels and chemicals has been the realization that petroleum stores are rapidly dwindling. Now, in the heart of Wisconsin, a project is underway to produce energy from a resource that is in little danger of running low: cow manure, or “brown gold.”

Thanks to a $7 million grant from the United States Department of Agriculture (USDA) Biomass Research and Development Initiative (BRDI), the University of Wisconsin-Madison and several state companies have formed a consortium to pilot the conversion of dairy farm manure into useful product streams—a project that is expected to have significant environmental and economic benefits.

The Accelerated Renewable Energy (ARE) project is already in progress at the 5,000-cow Maple Leaf Dairy in Manitowoc County, where animal waste is separated into different streams, or fractions, of processed manure.

After small plant fibers in the manure are separated out and anaerobically digested to create biogas, liquids from the digestion process are used to fertilize crops, while leftover solids can be converted into useful chemicals and bio-plastics. Larger plant fibers, on the other hand, make great animal bedding and mulch, not to mention a starting material for ethanol fermentation.

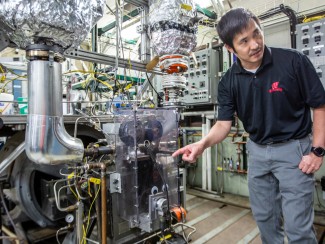

The ARE project dovetails nicely with the research of former WBI director and Biological Systems Engineering (BSE) faculty member Troy Runge, who is a co-investigator. Runge is interested in supporting a renewable energy economy through the development of value-added products from biomass. Having recently relocated to the new Wisconsin Energy Institute (WEI) building on the UW campus, Runge’s lab is analyzing the ARE project’s separation techniques to improve their efficiency and economic performance. These results and analyses will be among the first to come out of the WEI facility.

This is a triple-win situation; we would like to make money by doing the right thing by the environment and society.

Tom Cox

“We are performing many of the same separations that occur on the farm, but in the controlled environment of the lab to both measure and optimize the system,” says Runge.

Tom Cox, a CALS professor of agricultural economics and project collaborator, sees great potential for the initiative and its outcomes.

“This is a triple-win situation; we would like to make money by doing the right thing by the environment and society,” says Cox.

Aicardo Roa-Espinosa, the president of partner company SoilNet LLC and a BSE adjunct faculty member, developed the manure separation technology driving the project. Roa-Espinosa will work with Runge to study the separated manure fractions developed at Maple Leaf. The researchers will monitor the quality, quantity and composition of biogas produced from fermented manure. They will also separate processed manure into streams rich in fiber, protein, and/or nutrients, and then analyze them to identify chemical constituents using a range of analytical techniques. Finally, student researchers will conduct life cycle assessments to evaluate the project’s overall environmental impact with respect to greenhouse gases and carbon footprint.

“This is a great example of a multidisciplinary public-private partnership happening right at the WEI’s beginning,“ says Runge. “It’s also an example of a project that is important to Wisconsin.”

Indeed, the project has the potential to help farmers better manage manure to the benefit of soil, environment, and human health. A 5,000-cow dairy farm like Maple Leaf produces approximately 25 tons of manure per day, which require millions of gallons of water to manage. Although some manure may be used as fertilizer, nutrient imbalances and pollution caused by runoff can create environmental problems.

Fortunately, in addition to generating product streams that bring higher value to the farm, manure that is processed using SoilNet’s separation technology yields fertilizer that is concentrated and homogenized, allowing farmers to apply it with much greater precision and control over nutrient content. This method not only improves crop fertilization and limits pollution, but also recycles water.

In addition to its environmental benefits, the cellulosic—or non-food—plant biomass derived from dairy manure avoids any “food versus fuel” issues. This advantage lends even greater potential to the concept of the dairy farm as a cellulosic bio-refinery capable of supporting both a local green economy and a sustainable energy system.

“The foundation of sustainability is complementarity—the spillover of one process to another, possibly at a different point in time,” says Cox of the project’s intermingling environmental, economic, and social impacts. It is hoped that over the grant’s four-year lifetime, these piloted manure separation technologies will be improved until their sustainability benefits can be realized on an even broader commercial scale.